ENECML can include your PFC Maintenance as part of your COMA agreement, where we are already providing LV Maintenance services in addition to your HV agreement. Embedding all three services, takes away any worries about reliability of equipment, whilst spreading the cost of the service over the term of the agreement.

Please contact our team for a survey and initial estimate.

Power Factor Correction (PFC) aims to improve power factor, and therefore power quality. It reduces the load on the electrical distribution system, increases energy efficiency and reduces electricity costs. It also decreases the likelihood of instability and failure of equipment.

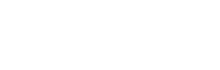

Power factor correction is obtained via the connection of capacitors which produce reactive energy in opposition to the energy absorbed by loads such as motors, locally close to the load. This improves the power factor from the point where the reactive power source is connected, preventing the unnecessary circulation of

current in the network.

An electrical network operating at unity Power Factor represents a system at 100% efficiency. Anything less than unity means that extra power is required to achieve the actual task at hand.

Power Factor Correction (PFC) is the term given to a technology that is used to restore Power Factor to as close to unity as possible and is normally achieved by the installation of capacitors (occasionally inductors) to the electrical network.

Reactive power charges can be eliminated to provide instant savings for the energy consumer. Power Factor Correction equipment should be serviced at least once per year to ensure that the capacitors within are still producing 100%. This ensures that you maintain those reactive power charge savings.

To ensure you continually make the potential savings on reactive power and availability charges, it is essential that any installed power factor correction equipment is serviced at least once every year.

Capacitors can deteriorate over time; the dielectric inside breaks down based on the number of occasions they are switched, the amount of time they are in operation and the number of external events they’re subjected to. It is therefore essential to consistently check the health of your PFC equipment, enabling it to continue to operate at an efficient power factor (>0.95) – the point at which charges will start to

be captured on your electricity bills.

PFC servicing can be added to your existing COMA, spreading the cost over the term of the contract and removing the management overhead of scheduling, as we will tie this into our inspection regime for the site.

ENECML: One contract for HV – LV – PFC and EICR.

Contact us today for a site, so we can manage your total network requirements.

Power quality is essential for efficient equipment operation, and power factor contributes to this.

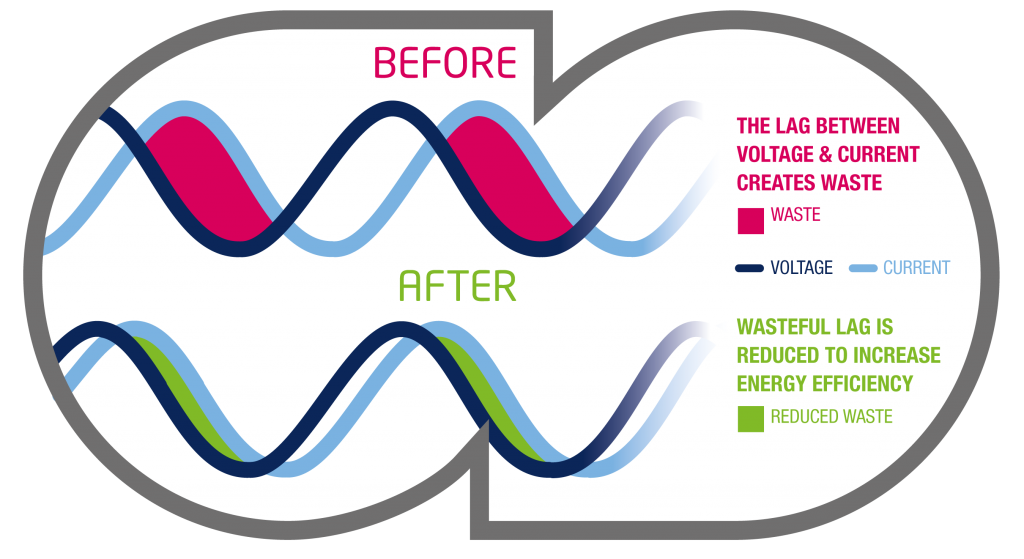

Power factor is the measure of how efficiently incoming power is used in an electrical installation. It is the ratio of active to apparent power, when:

– Active Power (P) = the power needed for useful work such as turning a lathe, providing

light or pumping water, expressed in Watt or KiloWatt (kW)

– Reactive Power (Q) = a measure of the stored energy reflected to the source which does

not do any useful work, expressed in var or Kilovar (kVAR)

– Apparent Power (S) = the vector sum of active and reactive power, expressed in Volt

Amperes or in KiloVolt Amperes (kVA)

The Power Triangle:

Poor power factor (for example, less than 95%) results in more current being required for the same amount of work. PFC corrects this aims to achieve unity power, saving energy for your site.

Call: 0845 0702520 for further information on Power Factor Correction

or email us at: sales@enecml.co.uk